Alfa Laval is a leading global provider of specialised products and engineering solutions within the key technology areas of heat transfer, separation and fluid handling. Our company was founded on a single brilliant invention and innovation remains at the heart of everything we do. Designed in Sweden with a commitment to product innovation, quality and engineering excellence, Alfa Laval heat exchangers provide efficient heat transfer with minimal fouling in compact equipment with a small footprint.

![]()

SPX FLOW, Inc. is a world leader in sustainable solutions that ensure the controlled and measured movements of life's essential elements. Based in Charlotte, North Carolina, with operations in more than 30 countries and sales to customers worldwide, our 5,000 employees innovate to design, deliver and service high-value solutions that make life safer, healthier, and more sustainable.

Our processing products and technologies provide a wide range of essential capabilities for customers across the food, beverage, and industrial markets. Our unique expertise spans generations and engineering disciplines, allowing us to solve complex challenges and create scalable solutions that meet the strategic objectives of the companies that nourish and build our world.

Sondex was established in 1984 and already has a presence is felt across the world with a network of sister companies punctuating important cities in USA, Australia, New Zealand, Romania, France, UAE, Poland, Netherlands, Italy, Germany and more countries are coming on line each year. Sondex prides itself on having a diverse product line of heat exchangers to suit your process, industry and application.

Due to the relationship forged over years of business together Delta T Technologies WA is recognised as a Preferred & Authorised Service Agent for Sondex in Western Australia.

![]()

Tranter manufactures the world’s most comprehensive range of highly efficient gasketed plate heat exchangers and all-welded plate heat exchangers. We work closely with our customers to achieve innovative, cost-effective solutions that deliver outstanding performance either as components in our customer’s products or processes or as complete integrated systems. Tranter manufacture more than 30 different sizes of heat exchangers plates, with connection size from 12.5 mm to 500mm representing the largest range of plates available on the market.

![]()

Mersen, formerly known as Carbone Lorraine is the world's leading manufacturer of corrosion resistant equipment. Mersen's range of solutions is unparalleled. Making use of multiple manufacturing facilities on every continent, Mersen can quickly deliver a broad palette of solutions ranging from impervious graphite, tantalum, zirconium, titanium, nickel alloys, PTFE lining, and silicon carbide. Equipment deliveries can be expanded to full system packages in the case of hydrochloric and sulphuric acid.

Fluonics manufactures corrosion resistant valves in South Korea. This company, with their many patents, is ahead of the field in innovating the future of lined valves. Their core products are their PFA lined valves however their new line of polymer lined composite valves is unique in their practical advantages and affordability.

![]()

GESMEX manufactures the revolutionary plate and shell heat exchanger in Germany. This heat exchanger is a game-changer since it has the performance expected from a plate exchanger yet it can be used in many of the applications previously strictly reserved for shell and tube equipment including high temperature and high pressure application. These products can often perform the same duty as a shell and tube in a fraction of the size and at a very advantageous cost.

Nexson Group is a specialist for spiral heat exchangers. They have the knowledge and experience to design your spiral to not only perform the duty required but also optimise design to minimise fouling and plugging.

We are fully equipped to meet your heat exchanger servicing and repair demands. This is achieved by proper assessment by experts with combined experience of 50+ years working with heat exchangers and determining the best method of repair.

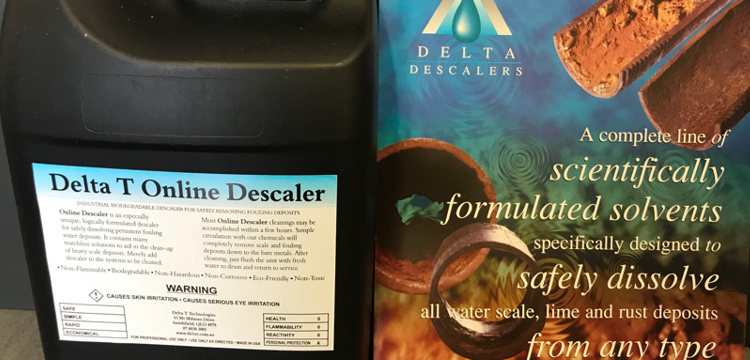

Our line of chemical formulations are designed to safely remove water scale, rust, lime and other deposits. We use an application specific process to restore your equipment to peak operating efficiency.

These can be supplied as Plate Packs (plates & gaskets), plates only or gaskets only. Having access to one of Australia’s largest and most diverse product ranges makes Delta T Technologies the ideal supplier to meet all your Plate Heat Exchanger needs.